Are you searching the best Custom Metal Cube?

Creating a custom metal cube sounds like a cool project! Here’s a general outline of the steps you might take:

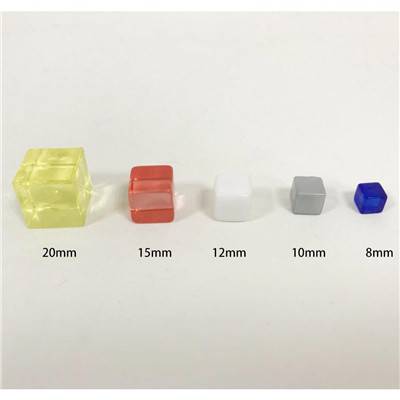

Design: Determine the dimensions and specifications of your metal cube. Consider factors like size, material, thickness, and any specific features or designs you want to incorporate. You can sketch your design on paper or use computer-aided design (CAD) software for more precision.

Material Selection: Choose the type of metal you want to use for your cube. Common options include steel, aluminum, brass, and copper. Each metal has its own properties and characteristics, so make sure to select one that suits your requirements in terms of durability, appearance, and cost.

Fabrication: Once you have your design and material selected, it’s time to start fabrication. If you have the necessary tools and skills, you can cut, bend, and weld the metal yourself. Alternatively, you can hire a metal fabrication shop to do the work for you. They will be able to accurately cut and shape the metal according to your specifications.

Finishing: After the fabrication process is complete, you may want to apply a finish to your metal cube to enhance its appearance and protect it from corrosion. Options for finishing include painting, powder coating, polishing, or leaving the metal bare for a more industrial look.

Quality Check: Once your metal cube is finished, carefully inspect it to ensure that it meets your expectations in terms of size, shape, and quality. Make any necessary adjustments or corrections as needed.

Enjoy: Now that your custom metal cube is complete, you can proudly display it as a unique piece of art or use it for whatever purpose you had in mind when you decided to create it.

Remember, safety is important when working with metal and metalworking tools, so make sure to take proper precautions and follow any relevant safety guidelines throughout the fabrication process.

Comments

Post a Comment